Installing a metal roof over existing shingles will likely cause more problems than it solves. If you opt to skip removing your old roof, you risk hidden moisture buildup, an irregular surface, and potential voided warranties.

Our recommendation is always to carefully remove the old roofing material before installing a new metal roof to ensure a flat, dry foundation and a warranty that remains fully intact.

We'll help you understand the potential challenges and whether the upfront savings truly make financial sense for your specific situation. Here is a breakdown of the six biggest issues, how they affect your roof's lifespan and warranty, and what you can do to minimize the risks if you still want to move forward.

Why homeowners consider installing metal roofing over shingles

While installing metal roofing over shingles can offer short-term benefits, our experience shows that this approach often creates challenges with moisture management, surface evenness, warranty coverage, and long-term durability. Understanding these trade-offs is crucial for making an informed decision.

The idea makes sense at first glance. You skip the tear-off, save on labor and disposal, and get your new roof faster. But here is the reality: covering up an old roof means covering up whatever is wrong with it. This is where complications can arise that many homeowners don't anticipate.

Let's walk through the six biggest problems so you know exactly what you are dealing with.

1. You cannot inspect or repair hidden roof decking damage

The roof deck is the plywood layer underneath your shingles. Everything attaches to it. When metal goes directly over old shingles, nobody gets to see what condition that plywood is in.

If there is rot, soft spots, or water damage from past leaks, it all stays hidden. The damage does not stop just because you covered it. It keeps getting worse, quietly, until you have a much bigger problem on your hands.

Here is what typically gets missed:

Rotted plywood: Water damage weakens the structure over time

Soft spots: Areas where the wood has deteriorated and cannot hold fasteners

Water stains: Signs of ongoing moisture problems that will continue under the new roof

In our experience, discovering these issues later often results in significantly higher repair costs compared to addressing them during an initial tear-off-which is why we always recommend a thorough inspection before making your decision.

2. The combined weight can stress your roof structure

Metal roofing is actually pretty lightweight on its own. But when you add it on top of existing shingles, your roof now carries both layers.

Older homes were designed for one roofing layer. The rafters and trusses were sized for that load, not double. Over time, the extra weight can cause stress on the framing.

Most building codes limit roofs to two layers total. If your home already has two layers, you'll need to remove the old materials before installing a new metal roof to avoid potential fines, structural damage, or voided warranties.

3. Essential roofing components get skipped

A roof is more than just the visible covering. Several components work together to keep water out. When roofers install metal over shingles, they often cannot replace the parts that matter most.

Underlayment

Underlayment is the waterproof barrier that goes between your roof deck and your roofing material. Think of it as a backup layer that catches any water that sneaks past the outer surface.

When you install over old shingles, fresh underlayment cannot go where it belongs, which is directly on the decking. The old underlayment, if it is even still intact, stays in place. And it may already be failing.

Flashing

Flashing is the metal strips that seal the joints around chimneys, vents, skylights, and roof edges. Water loves to find its way into these spots, and flashing is what stops it.

During an overlay, old flashing typically stays in place. If it is corroded or improperly sealed, leaks will follow. Replacing flashing properly usually requires access to the roof deck.

Drip edge

Drip edge is the metal strip along the edges of your roof that directs water into the gutters. Without it, water can run down behind the fascia and cause rot.

Installing drip edge correctly means attaching it to the roof deck. That is difficult or impossible when you are layering over shingles.

4. Future leaks are harder to find and fix

With two roofing layers, water can travel sideways between them before it ever shows up inside your home. By the time you see a water stain on your ceiling, the actual leak could be several feet away.

What might have been a straightforward repair can become a more complex and costly project.

A straightforward leak repair on a single-layer roof typically costs $300 to $800. The same leak on a layered roof can easily cost $800 to $2,000 because roofers need to remove both layers to find and fix the problem.

5. Moisture and condensation can get trapped between layers

Trapped moisture is one of the most serious problems with installing metal over shingles. When moisture has nowhere to escape, it creates conditions for mold, mildew, and wood rot.

Trapped moisture under metal panels

Shingles absorb and hold heat. When metal panels go over them, temperature changes cause condensation to form between the layers. That moisture has nowhere to go.

Over time, this leads to damage in the structure below. You might not see it for years, but it is happening. And once rot sets in, the repair costs climb quickly.

Poor attic ventilation

A healthy roof relies on air moving from the soffit vents at the eaves up to the ridge vents at the peak. This airflow keeps moisture from building up in your attic.

Adding a metal layer over shingles can block or reduce this airflow. The result is more condensation, higher humidity in the attic, and in colder climates, worse ice dams.

6. Existing roof problems do not go away

If your current shingle roof has curling, missing pieces, or an uneven surface, all of that transfers directly to the metal roof above. Covering up problems does not fix them.

Here is what happens:

Wavy, rippled panels: Metal panels can develop a wavy, rippled appearance (called oil canning) when installed over an uneven surface.

Granule wear: The rough texture of shingle granules acts like sandpaper against the underside of metal panels, causing premature deterioration.

Uneven fastening: Screws may not seat properly on an irregular surface, leading to loose panels or leaks down the road.

If your existing roof is in rough shape, the new metal roof will show it.

How installing metal over shingles affects warranties and insurance

Beyond the physical issues, layering roofs can create financial risks that catch homeowners off guard.

Manufacturer warranty issues

Most metal roofing manufacturers require installation over clean, flat decking. Installing over shingles may void the warranty entirely. If something goes wrong, you may have no coverage.

Before you agree to an overlay, ask your roofer to confirm in writing that the manufacturer warranty will still apply.

Home insurance considerations

Some insurers view layered roofs as higher risk. If you file a claim for water damage, the insurance company may deny it if the installation did not follow code or manufacturer guidelines.

It is worth a quick call to your insurance agent before making a decision.

Resale value concerns

Home inspectors often flag layered roofs. Buyers may negotiate a lower price or request a full tear-off before closing. You could end up paying for proper installation anyway, just at a less convenient time.

Is it legal to put a metal roof over shingles

In the Chattanooga area, local building codes and our climate conditions create specific considerations for metal roof installations that homeowners should keep in mind.

The answer depends on your local building codes. Many areas allow only two roofing layers total. Some require a full tear-off before any new roof installation.

Before moving forward, check with your local building department or ask your roofer about permit requirements. The rules apply whether you are installing steel, aluminum, or any other type of metal roofing.

How long does a metal roof over shingles last

A properly installed metal roof can last 40 to 70 years. But a metal roof installed over shingles will likely not reach that potential.

Trapped moisture, hidden damage, and ventilation issues all shorten lifespan. You might save money upfront, but you may end up replacing the roof sooner than expected. When you factor in these potential issues, the initial cost savings may not provide the long-term value you're seeking.

How to minimize problems when installing metal over shingles

If you still want to install metal over existing shingles, there are ways to reduce the risks. None of these are perfect solutions, but they help.

1. Inspect the roof deck before installing

Have a roofer check for soft spots, sagging, or visible damage. Some inspections can be done from the attic without removing shingles. At minimum, you want to know what you are covering up.

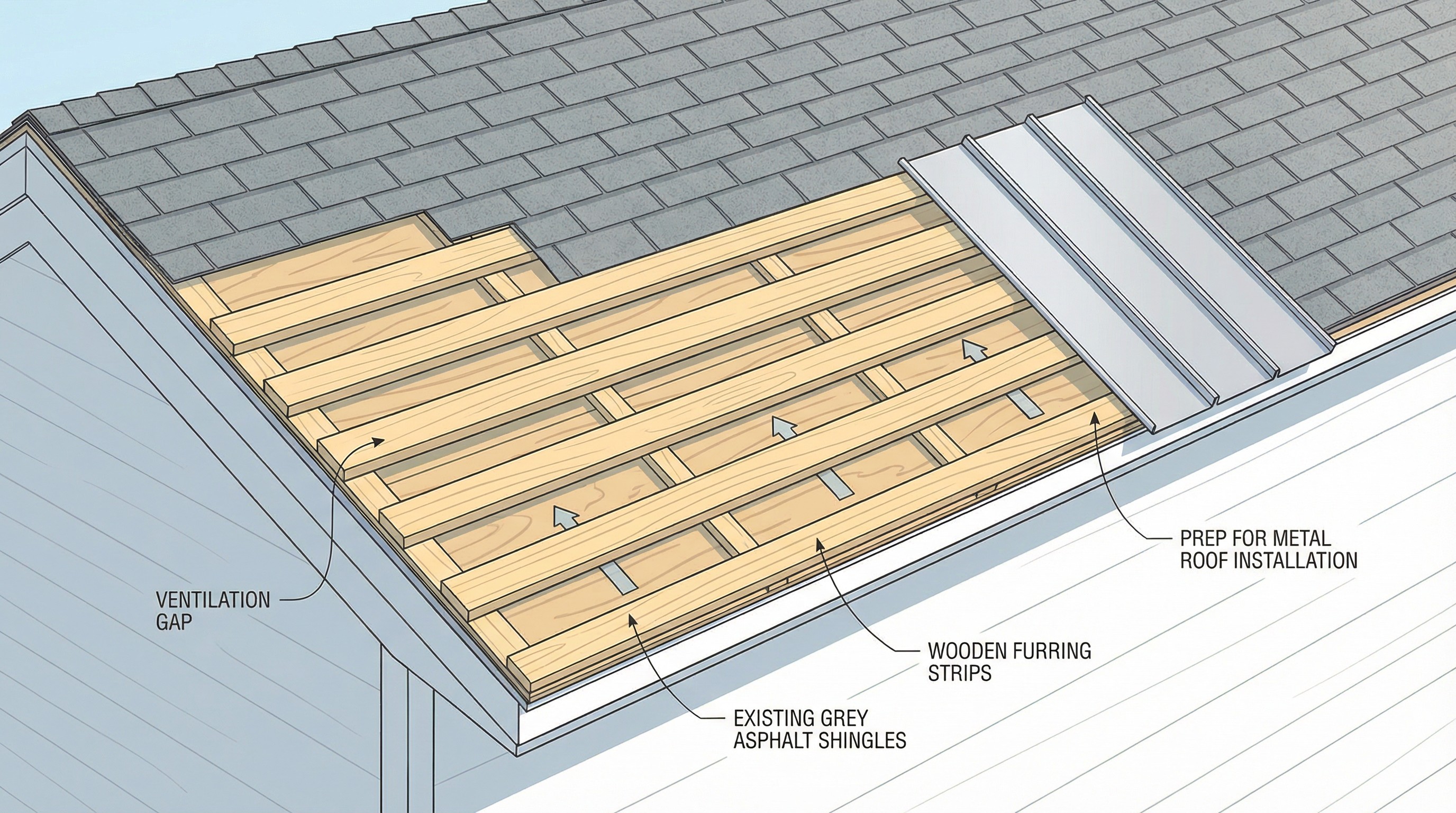

2. Add furring strips for airflow and a level surface

Furring strips are thin wood boards attached to your roof that create a small air gap between the old shingles and new metal. Think of them like spacers that help air flow and level out bumps.

3. Use a synthetic underlayment barrier

Placing synthetic underlayment between the shingles and metal adds a moisture barrier and protects against granule abrasion. It is not as good as underlayment on clean decking, but it helps.

4. Improve attic ventilation

Adding or upgrading soffit vents, ridge vents, or gable vents helps keep air moving and reduces condensation risk. This is especially important when you are adding a layer that can trap moisture.

5. Hire a qualified roofing professional

This type of installation requires experience. A skilled roofer will know local codes, proper techniques, and when to recommend a tear-off instead. A qualified roofer should always discuss both the benefits and potential challenges of overlay installation to help you make an informed decision.

How to compare quotes and make the right decision

When getting quotes for a metal roof, ask each roofer whether they recommend installing over shingles or doing a tear-off. Get quotes for both options so you can compare the true costs.

Request line-item pricing: Understand what you are paying for labor, materials, and disposal separately

Check for warranty coverage: Confirm the manufacturer warranty applies to the installation method being proposed

Verify permits and codes: Make sure the roofer will pull permits and follow local requirements

In many cases, when you compare detailed quotes for both approaches, the cost difference may be less significant than initially anticipated.

Tip: If you want help comparing vetted roofing quotes, roofquotes.com makes it easy to see your options and choose with confidence.