Flat roof installation requires specialized techniques and careful material selection to perform well over 20-30 years. Whether you are replacing an old flat roof on your garage or installing a new membrane on a commercial building, understanding your material options and the proper installation process helps you avoid the costly mistakes that commonly lead to premature roof failure and expensive repairs down the road. This comprehensive guide covers everything you need to know about flat roof installation, from choosing the right waterproofing membrane for your specific local climate to understanding true project costs and making the important decision between attempting DIY flat roof installation yourself and hiring experienced professional roofing contractors for the work.

What Is Flat Roof Installation?

Flat roof installation is the process of applying a waterproof membrane system to a low-slope roof structure. Despite the common name, flat roofs are not actually flat at all. They require a slight slope of 1/4 inch to 1/2 inch per foot for proper water drainage toward drains or scuppers. Without this minimal pitch, water pools on the surface and causes rapid premature membrane failure through constant exposure.

Flat roof installation is extremely common on commercial buildings of all types, residential garages and carports, porch and patio roof covers, home additions and extensions, and modern architectural homes. The flat roof installation process relies entirely on continuous membrane waterproofing rather than the gravity-driven water shedding from overlapping shingles that traditional pitched roofs use for weather protection.

The key components of any professional flat roof installation include a solid substrate or deck (typically plywood or OSB sheathing), an insulation layer that provides energy efficiency and prevents condensation, a waterproofing membrane that serves as the primary weather barrier, flashing at all edges, penetrations, and transitions to prevent water infiltration, and a drainage system with internal drains or scuppers to effectively remove water from the roof surface. Professional roof inspection before flat roof installation helps identify substrate issues. Proper installation of each component is critical for long-term performance.

Types of Flat Roof Materials

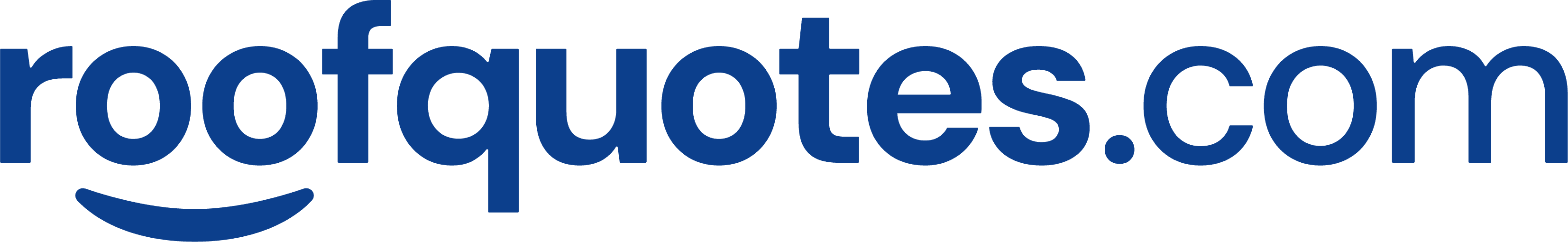

Material choice significantly affects your flat roof installation costs, expected lifespan, energy efficiency characteristics, and long-term maintenance requirements. Here are the five most common flat roofing material options with their key performance characteristics and typical installed costs.

EPDM Rubber Roofing

EPDM rubber is the single most popular residential flat roof material in North America. This flexible black rubber membrane is extremely durable, highly UV-resistant, and the only flat roofing material truly suitable for DIY flat roof installation by homeowners with basic construction skills.

EPDM lasts 20-30 years when installed correctly and costs $3-5 per square foot for complete professional installation. The seams where individual membrane sheets meet are sealed using special EPDM seam tape or liquid adhesive, making the flat roof installation process more forgiving for beginners compared to heat-welded materials that require expensive specialized welding equipment.

However, those adhered seams can become weak points if not installed correctly with proper surface cleaning, priming, and pressure application. The dark black color also absorbs significant heat from direct sunlight, which can increase cooling energy costs in hot southern climates by 10-15% compared to white reflective membrane alternatives like TPO or PVC.

TPO (Thermoplastic Polyolefin)

TPO has rapidly become the fastest-growing commercial flat roof material over the past decade. This bright white membrane reflects solar radiation very effectively, helping reduce building energy costs by up to 15% compared to heat-absorbing darker materials like EPDM or modified bitumen.

TPO flat roof installation typically lasts 15-25 years and costs $4-8 per square foot installed. The seams are heat-welded together using a specialized hot-air welding gun that precisely heats the overlapping material to 400-600°F, creating a molecular bond that is actually stronger than the membrane material itself when the flat roof installation is performed correctly by properly trained installers.

The main downsides to TPO are that manufacturing quality and chemical formulation vary significantly between different TPO brands (some manufacturers have experienced issues with premature cracking), and TPO has a considerably shorter real-world performance track record than EPDM since it only became widely popular in the roofing industry within approximately the past 20 years.

PVC Roofing

PVC is the premium choice for commercial flat roof installation applications, especially for buildings where chemical exposure from grease, oils, or industrial processes is a significant concern. Restaurants with kitchen exhaust grease, manufacturing facilities, and buildings located near salt water often specifically choose PVC for its superior chemical resistance characteristics.

PVC flat roof installation typically lasts 20-30 years and costs $6-10 per square foot installed, making it the most expensive common flat roofing material option. Like TPO, the seams are heat-welded together for exceptional strength and reliability. PVC is also highly fire-resistant and handles repeated freeze-thaw temperature cycles better than other available membrane materials. The higher upfront installation cost compared to EPDM or TPO is the primary drawback for budget-conscious projects.

Modified Bitumen

Modified bitumen is an asphalt-based roofing system that comes in rolls and is applied in multiple layers during flat roof installation. It is typically torch-applied, where experienced roofers use propane torches to carefully heat the material until the asphalt backing melts and bonds directly to the substrate or previous layer below.

Modified bitumen flat roof installation typically lasts 10-20 years and costs $3-6 per square foot installed. It is quite durable and works effectively in both residential and commercial flat roof installation applications. However, the torch application process carries real fire safety risks that make it completely unsuitable for DIY installation and requires experienced, properly insured professional roofers. Like EPDM, the dark surface color absorbs heat significantly, which increases cooling costs in warm climates.

Built-Up Roofing (BUR)

Built-up roofing is the traditional tar and gravel flat roof installation method that has been used successfully on commercial buildings for well over 100 years. Multiple alternating layers of asphalt-saturated reinforcing felt and hot liquid asphalt are built up on the roof deck during installation, then topped with gravel or slag aggregate for UV radiation protection and surface durability.

BUR flat roof installation typically lasts 15-30 years and costs $5-10 per square foot installed. It is heavy, extremely labor-intensive, and messy to install, requiring multiple experienced crew members and specialized hot asphalt application equipment. However, the exceptional proven longevity and 100+ year performance track record make it popular for large commercial flat roof installations where long-term performance history matters more than installation convenience or building aesthetics.

Material Comparison Table

Material | Lifespan | Cost/SF | Best Application | Energy Efficiency |

|---|---|---|---|---|

EPDM | 20-30 years | $3-5 | Residential, DIY | Moderate (dark absorbs heat) |

TPO | 15-25 years | $4-8 | Commercial | Excellent (white reflects) |

PVC | 20-30 years | $6-10 | Commercial, chemical | Excellent (white reflects) |

Modified Bitumen | 10-20 years | $3-6 | Residential, commercial | Moderate (dark absorbs heat) |

BUR | 15-30 years | $5-10 | Large commercial | Good (gravel reflects) |

According to the National Roofing Contractors Association (NRCA), proper material selection based on climate conditions and specific application is the most critical success factor in flat roof installation projects.

Flat Roof Installation Cost Breakdown

Understanding what drives flat roof installation costs helps you evaluate contractor quotes accurately and budget appropriately for your specific project needs.

Cost by Material Type

Material selection is the single biggest cost factor in any flat roof installation project. EPDM costs $3-5 per square foot installed. TPO costs $4-8 per square foot. PVC costs $6-10 per square foot. Modified bitumen costs $3-6 per square foot. Built-up roofing costs $5-10 per square foot installed.

For a typical 400 square foot residential garage flat roof installation, expect to pay $1,200-$2,000 for EPDM, $1,600-$3,200 for TPO, $2,400-$4,000 for PVC, $1,200-$2,400 for modified bitumen, or $2,000-$4,000 for built-up roofing including materials and professional labor.

For larger 5,000 square foot commercial flat roof installations, total costs range from $15,000-$25,000 for EPDM, $20,000-$40,000 for TPO, $30,000-$50,000 for PVC, $15,000-$30,000 for modified bitumen, or $25,000-$50,000 for built-up roofing.

Labor Costs

Labor typically represents 50-60% of your total flat roof installation cost. Professional installation labor alone runs $1.50-$4 per square foot, varying based on material type, roof size, complexity, and location. Torch-applied materials cost more due to specialized equipment. Larger flat roof installations benefit from economies of scale. Complex roofs with many penetrations cost more. Urban areas command higher wages. Most residential installations (400-800 SF) complete in 1-2 days. Commercial projects (5,000+ SF) take 3-7 days.

Additional Costs

Tear-off of existing roofing adds $1-2 per square foot. Insulation installation adds $1-3 per square foot depending on R-value. New decking costs $2-4 per square foot if substrate is damaged. Flashing and edge work costs $5-15 per linear foot. Building permits run $200-500. Dumpster rental costs $300-800.

Energy Star reports that proper insulation and cool roof material selection during flat roof installation can reduce annual energy costs by 10-20%.

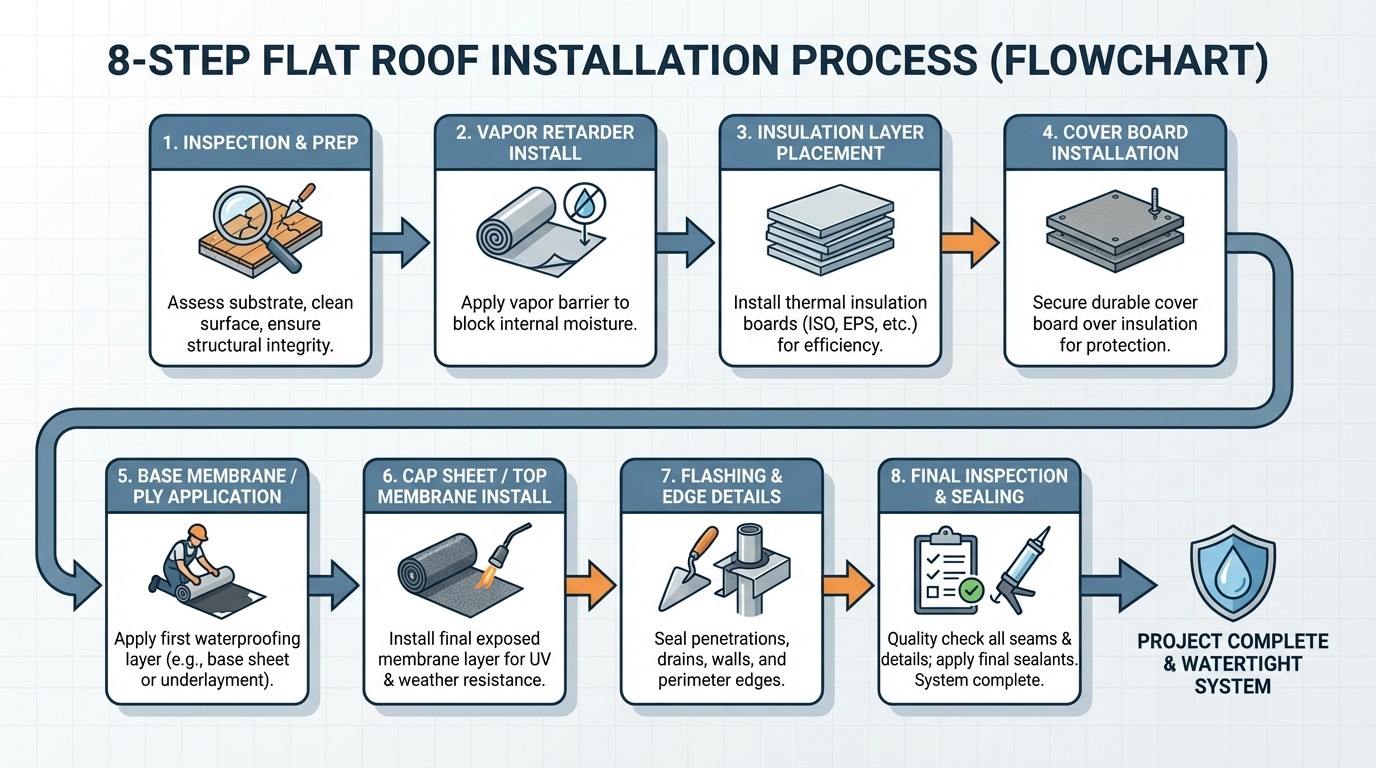

Installation Process

Professional flat roof installation follows 8 systematic steps.

Step 1: Inspect substrate for damage, measure area, identify penetrations, check drainage, plan layout to minimize seams.

Step 2: Tear off old membrane if replacing, inspect decking for hidden damage, replace rotted wood, dispose materials properly (adds 1 day).

Step 3: Install new decking if needed, ensure smooth surface, create 1/4 inch per foot slope for drainage. Improper substrate causes 80% of flat roof installation failures.

Step 4: Install rigid foam insulation boards (R-10 to R-30), fasten or adhere securely, use tapered panels for slope if needed.

Step 5: Apply membrane,EPDM uses tape/adhesive with primer, TPO/PVC heat-weld at 400-600°F, modified bitumen is torch-applied, BUR builds multiple layers. Seams overlap 3-6 inches.

Step 6: Install flashing at edges, penetrations, walls, drains. Most flat roof installation leaks occur at flashings.

Step 7: Seal all penetrations with boot flashings, add edge metal and coping, seal fasteners. 70% of leaks occur here.

Step 8: Check seams and flashings, verify drainage, test if required. Residential takes 1-2 days, commercial 3-7 days.

Residential vs Commercial

Approaches differ by application.

Residential: Common on garages, porches, additions, modern homes. Use EPDM, TPO, modified bitumen. Size 200-800 SF, cost $800-$6,000. EPDM is DIY-friendly. Permits needed over 120 SF. Consider HOA restrictions, architectural style, snow load capacity.

Commercial: Standard on offices, retail, warehouses, apartments. Use TPO, PVC, BUR. Size 5,000-50,000+ SF, cost $15,000-$500,000+. Never DIY. Always need permits and often engineer plans. Must meet fire rating codes, wind uplift requirements, warranty minimums (15-20 years), handle equipment loads and foot traffic.

Climate Selection

Climate drives flat roof installation material choice.

Hot: White TPO or PVC reflects heat, saves 10-15% cooling. Avoid dark EPDM.

Cold: EPDM or PVC stays flexible when frozen. Use R-30+ insulation. Verify snow load (20-60 PSF).

Wet: Fully adhered membranes, multiple drains, 1/4 inch slope. Light colors resist moss.

Coastal: PVC for salt resistance, fully adhered for wind.

DIY vs Professional

DIY Works: Projects under 500 SF, simple shapes, EPDM only, minimal penetrations, previous experience. Saves 40-50%. Example: 400 SF garage costs $600-1,200 DIY vs $1,200-2,000 professional. Time: 2-3 days vs 1 day.

Hire Professionals: All commercial, heat-welded membranes (need equipment), torch materials (fire risk), complex shapes, over occupied spaces, permits needed. Benefits: 10-30 year warranties, code compliance, insurance, faster, lower risk. See our roofer questions guide.

Common Mistakes

Poor Drainage: Ponding water (standing 48+ hours) voids warranties and causes failure. Ensure 1/4 inch per foot slope minimum.

Dirty Seams: Causes seam failures within 1-3 years. EPDM needs primer on both surfaces. TPO/PVC needs proper weld temperature (400-600°F) with clean edges.

No Insulation: Skipping insulation costs more through energy loss and condensation. Use minimum R-10, optimal R-20-R30. Pays back in 5-7 years.

Bad Flashing: Rushing flashing causes 70% of flat roof installation leaks. Follow manufacturer specifications exactly.

Wrong Material: Dark membranes in hot climates increase cooling costs 15-25%. Some crack in extreme cold. Match material to climate.

Damaged Substrate: Installing over bad decking fails within months. Always inspect and repair substrate before flat roof installation.

Maintenance

EPDM: Inspect twice yearly (spring, fall). Clear drains. Check seams for separation, reseal if needed. Clean with mild soap, avoid petroleum cleaners. Reseal seams every 10-15 years. TPO/PVC: Inspect twice yearly. Keep surface clean for reflectivity. Check seams. Professional inspection every 3-5 years. Modified Bitumen: Inspect quarterly. Recoat with reflective coating every 5-7 years. Repair issues promptly. BUR: Inspect twice yearly. Maintain gravel layer. Recoat with asphalt every 5-10 years. Lasts 30+ years with care. Learn about roof longevity.