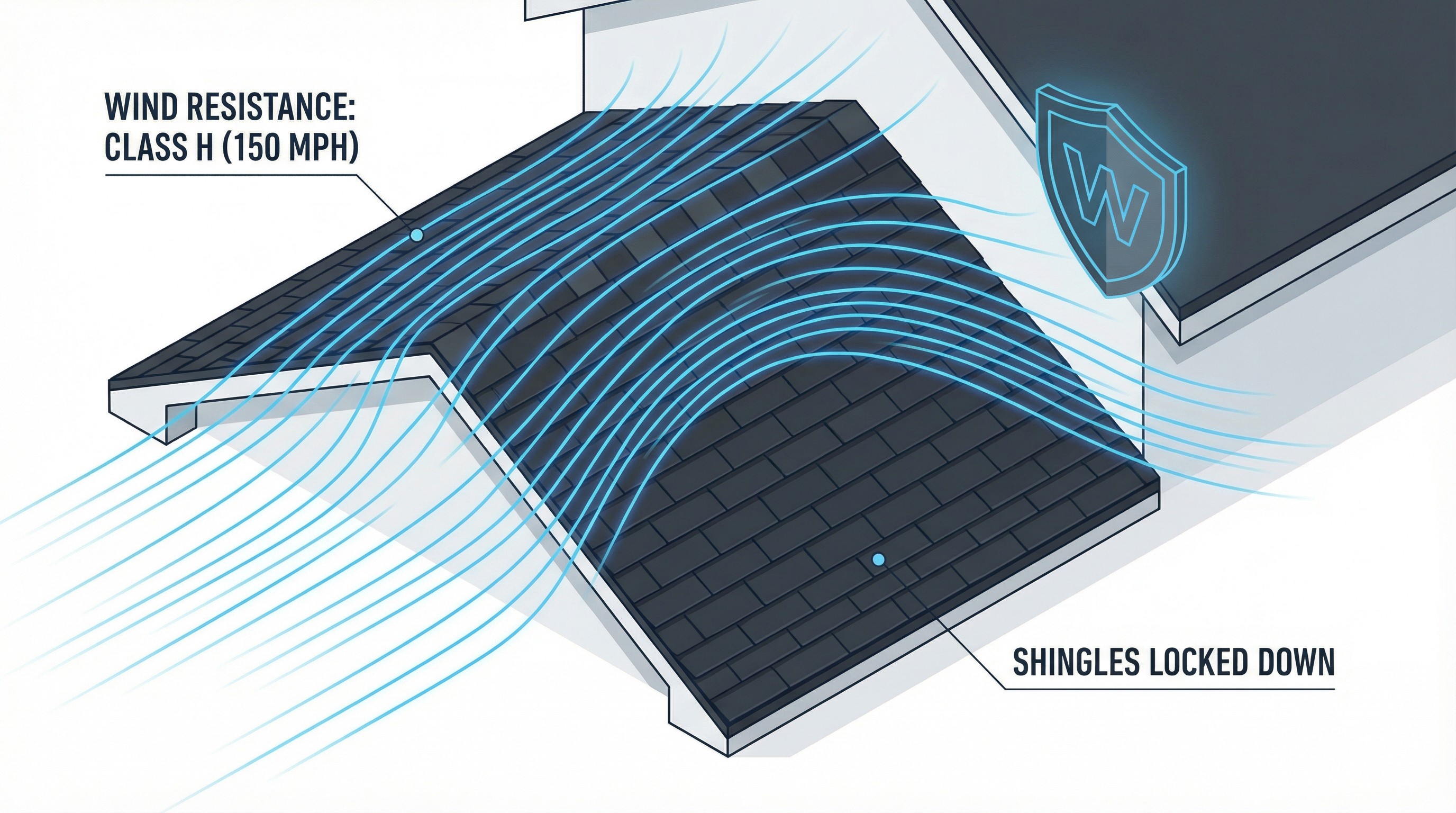

Class H shingles are the strongest wind-resistant asphalt shingles, tested to withstand 150 mph winds. If shingles lift during a storm, water gets underneath fast; damage spreads within hours. Wind ratings matter, and Class H shingles represent the highest level of wind protection available with asphalt roofing.

Class H shingles are asphalt roofing shingles tested to resist wind speeds up to 150 mph under the ASTM D7158 standard. This guide explains how Class H compares, brands offering it, whether your home needs it, and what to expect when getting quotes.

What Are Class H Shingles

Class H shingles are asphalt roofing shingles designed to resist wind forces up to 150 mph. The "H" refers to an ASTM D7158 classification, measuring how well shingles stay sealed when wind tries to lift them. Class H on a label means that shingle passed the most rigorous wind resistance test available for asphalt roofing.

What Actually Sets Class H Apart?

Think of Class H as the heavy-duty option. While standard shingles are fine for average weather, Class H shingles are engineered specifically to stay on your roof when things get extreme.

Here is the breakdown of the difference:

150 mph Wind Rating: While basic shingles often fail around 60 mph, Class H is rated to hold fast up to 150 mph. That is the difference between surviving a standard thunderstorm and a Category 4 hurricane.

The "Torture Test" (ASTM D7158): This code means the shingle passed rigorous lab testing against hurricane-force uplift. It proves the material will stay flat rather than lifting or ripping off when the wind hits from tricky angles.

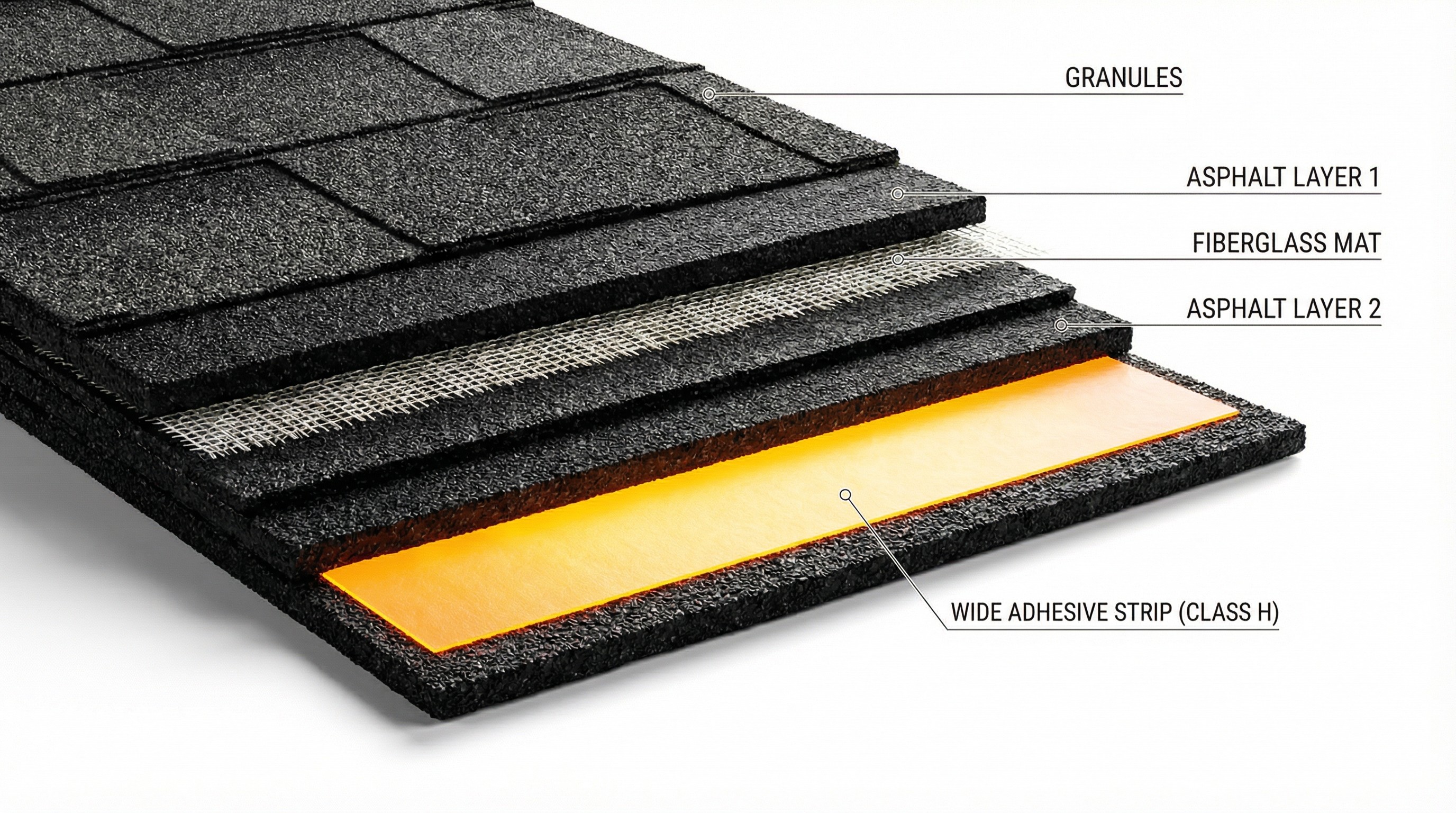

Stronger Seal: It's not just about weight; it's about the grip. Class H shingles use aggressive adhesive strips that, once heated by the sun, fuse the shingle to the roof deck to prevent wind from getting underneath.

The rating matters because wind damage happens in minutes. Once shingles lift, water enters quickly, causing serious leaks.

How Class H Compares to Other Wind Ratings

Not all wind-resistant shingles perform the same. The industry uses different standards; understanding labels helps you make informed comparisons.

ASTM D7158 Wind Classifications

ASTM D7158 divides shingles into three classes based on wind performance. Class D covers basic protection, Class G offers moderate resistance, and Class H provides the highest level available.

Class | Wind Speed | Common Shingle Type |

|---|---|---|

D | Up to 90 mph | Basic 3-tab shingles |

G | Up to 120 mph | Standard architectural shingles |

H | Up to 150 mph | Premium architectural shingles |

Most homes in areas seeing occasional thunderstorms do fine with Class G. However, if your area gets storms with winds over 90 mph more than once per year, Class H provides better protection.

ASTM D3161 Class F and Other Standards

You'll also see ASTM D3161 Class F ratings. This older method measures wind resistance differently. Class F is the top rating under this system, indicating resistance to winds around 110 mph.

Many manufacturers test under both standards. While both are useful, ASTM D7158 is considered more comprehensive because it tests shingles the way wind actually hits your roof, rather than just measuring uplift force. If comparing products and both ratings appear, focus on the ASTM D7158 classification.

Benefits of Class H roof shingles

Whether the investment makes sense depends on local weather patterns and how long you plan to stay.

Superior Wind Resistance

Class H shingles use wider, stronger adhesive strips bonding each shingle to the one below. The nailing pattern is also more precise. When installed correctly, shingles stay flat even when wind speeds spike.

For Chattanooga homeowners, this matters during spring and summer thunderstorms. The National Weather Service reports Chattanooga sees wind gusts over 70 mph about 3-4 times per year, with some storms reaching 90+ mph.

Improved Durability and Longevity

Shingles resisting wind damage last longer. When shingles flap or lift repeatedly, they crack and lose protective granules. This wear shortens the roof's lifespan, creating weak spots where leaks start.

Expect 25-40 years from Class H shingles when installed properly and maintained. Homes in harsh climates or with poor ventilation see closer to 25 years; well-maintained roofs in moderate climates can reach 35-40 years.

Potential Insurance Premium Discounts

Some insurance companies offer discounts when you install wind-resistant roofing. These vary, but one homeowner in Florida saved about $200 a year. Call your insurance agent to find out how much you could save. Get the answer in writing to factor it into your budget.

Popular Class H Shingle Brands

Several major manufacturers produce Class H rated shingles. Knowing which products to ask about helps you have informed conversations with contractors.

GAF Timberline HDZ

You will see this shingle everywhere, and for good reason. GAF uses something they call "LayerLock technology." In plain English, they mechanically fuse the layers of the shingle together so they stay put. They also widened the nailing zone, which makes it harder for installers to miss the mark, ensuring a tighter seal.

Estimated Material Cost: $90 – $130 per square.

Owens Corning Duration

Owens Corning takes a different approach with their "SureNail" technology. If you look at the shingle, you'll see a distinct fabric strip running right across the nailing area. This strip gives the nails something solid to bite into, preventing them from pulling through during heavy gusts. It’s a favorite among roofers because you can physically feel the difference in grip.

Estimated Material Cost: $95 – $140 per square.

CertainTeed Landmark

If aesthetics are your main concern, CertainTeed Landmark is often the go-to. They use a dual-layer design that creates a deeper shadow line, making the roof look thicker and more textured than some competitors. It still offers that Class H wind resistance but is often the most budget-friendly entry point in the premium category.

Estimated Material Cost: $85 – $125 per square.

Do You Actually Need Class H Shingles?

Just because Class H is the "best" rating doesn't mean it's necessary for every single house. If you live in a low-wind valley, paying for maximum wind resistance might be overkill.

However, we usually recommend upgrading to Class H if:

Your house is exposed: If you live on a hilltop, a ridge line, or right next to a large open field, there are no trees or buildings to break the wind before it hits your roof.

You live in storm country: If your area is prone to severe thunderstorms, tornadoes, or tropical depressions, the extra grip is cheap insurance against blown-off shingles.

You want an insurance break: It is worth calling your insurance agent. In some high-risk zip codes, installing Class H shingles can actually lower your home insurance premiums.

You are playing the long game: If this is your "forever home," durable shingles usually pay for themselves by reducing the need for minor repairs after every bad storm.

In Chattanooga, spring and summer storms bring sudden high winds. The area occasionally sees remnants of tropical systems. While Class H isn't always necessary, it's worth discussing if your home sits in an exposed location.

If you live in a sheltered neighborhood and budget is tight, Class G shingles (rated to 120 mph) offer solid protection at lower cost.

How to Get Quotes for Class H Shingle Installation

Once you've decided Class H shingles make sense, the next step is finding qualified roofers. Even the best shingles fail if installation doesn't follow manufacturer specifications.

Start by requesting quotes from three local roofing contractors. Ask specifically whether they have experience installing Class H shingles and request references. A good contractor will provide detailed line-item quotes breaking down costs. Avoid contractors giving a single total price, making it impossible to verify fair pricing.

A qualified contractor should explain specific nailing patterns, adhesive requirements, and installation steps making Class H shingles perform as rated. If they can't walk you through details, that's a red flag.

For Chattanooga homeowners, this is why roofquotes.com was created. Instead of calling contractors individually, get five detailed, line-item quotes from vetted local roofers in one place. The escrow payment system protects you, and because contractors don't pay sales commissions, you typically save around 20%.