You've probably seen parapet walls hundreds of times without knowing what they’re called. That low wall around the edge of a flat roof is a parapet, and it keeps water from spilling over the side while providing a protective barrier for anyone up there. Next steps: check if your roof has one.

A parapet wall is a low protective barrier that extends above a roof's edge, serving as a safety guard, weather shield, and architectural feature all at once. This guide explains what parapet walls are, why they matter for your roof, the most common problems they develop, and how to maintain them so they protect your building instead of causing expensive leaks.

What Is A Parapet Wall

A parapet wall is a low protective wall that extends above the edge of a building's roof, balcony, or terrace. You'll see parapet walls most often on flat roofs, where they rise anywhere from a few inches to several feet above the roof surface. The word comes from the Italian "parapetto," which literally means "to shield the chest."

While the terminology may be unfamiliar, parapet walls are common architectural features on many commercial buildings and some residential properties.

Parapet walls serve several practical purposes. They prevent people from falling off roof edges, protect the roof perimeter from wind damage, and can slow the spread of fire between adjacent buildings. Many parapets also hide rooftop equipment like HVAC units, giving buildings a cleaner appearance from street level.

The materials used to build parapet walls vary based on the building's design:

Masonry: Brick, stone, or concrete block (the most traditional choice)

Metal: Steel or aluminum panels (lighter and more modern)

Wood: Framed walls with siding to match the building

Glass: Contemporary designs that maintain visibility

Types of Parapet Walls

Parapet walls come in several styles, mostly distinguished by their appearance. Knowing which type you have helps when talking with contractors about repairs or maintenance.

Plain Parapet Walls

Plain parapets are exactly what they sound like. The wall extends straight up from the roof edge without any decorative elements. This is the most common type you'll find on commercial buildings and modern residential flat roofs. Plain parapets offer homeowners the advantage of straightforward maintenance and typically lower repair costs due to their simple design.

Perforated Parapet Walls

Perforated parapets have patterns of openings cut through the wall. The holes serve both decorative and functional purposes, allowing air to move through while still providing a safety barrier. You'll often see this style on historic buildings or structures where architectural detail matters.

Paneled Parapet Walls

Paneled parapets feature decorative panels or recessed sections built into the wall face. This creates visual depth and makes the parapet a more prominent architectural feature. Older commercial buildings frequently use this style.

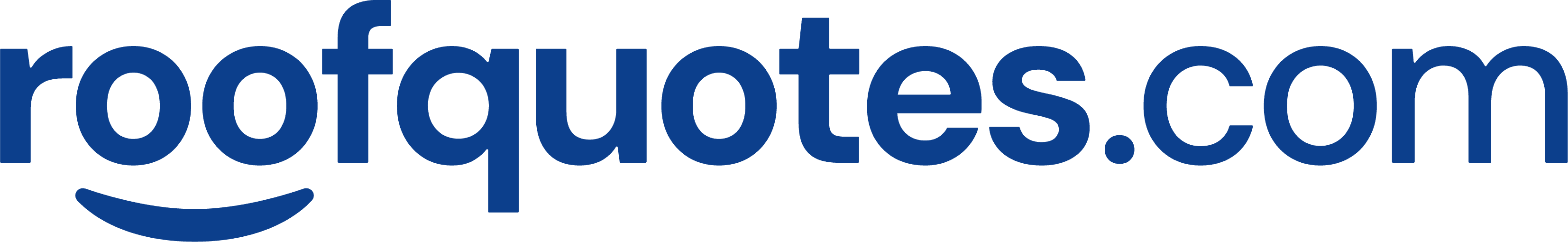

Embattled Parapet Walls

Embattled parapets look like castle walls, with alternating high and low sections. While originally designed for defense in medieval times, today they're purely decorative. You might see them on government buildings, universities, or structures designed to look historic or imposing.

Stepped Parapet Walls

Stepped parapets follow a stair-step pattern, often rising alongside a sloped roof. This design is common in Spanish Colonial and Mission-style architecture, where the parapet creates a distinctive roofline silhouette.

Why Parapet Walls Matter for Your Roof

Parapet walls do more than frame the edge of a roof. They protect both the building and the people who use it in ways that aren't always obvious.

Fall protection and safety

Parapets create a physical barrier at the roof edge. This matters most on flat roofs where maintenance workers access HVAC equipment or on buildings with rooftop terraces. Building codes often require parapets of a certain height when a roof is accessible or when workers regularly perform maintenance.

Wind and weather protection

The roof edge faces the greatest wind stress during storms, making proper parapet design crucial for protecting your roofing system.

Fire barrier between buildings

In densely built areas, parapets slow the spread of fire from one building to an adjacent structure. The wall acts as a vertical barrier that prevents flames from jumping across narrow gaps. This is why building codes in many urban areas require parapets on commercial buildings and multi-family structures.

Hiding rooftop equipment and improving appearance

Rooftop HVAC units, vents, and pipes can be unsightly from street level. Parapet walls tall enough to conceal this equipment create a cleaner appearance. Beyond hiding equipment, parapets add architectural character and make a simple flat roof building look more substantial.

What Does a Parapet Wall Look Like

When you look at a building with a flat roof from the street, the parapet is that short wall rising above the roofline. The most visible part is usually the coping, which is the protective cap sitting on top of the wall. This cap might be metal, stone, concrete, or another durable material.

Most parapet walls stand between 18 inches and 4 feet tall, though some decorative parapets go higher. The wall itself typically matches the building's exterior finish, whether that's brick, stucco, siding, or another material.

Which Roofs Have Parapet Walls

Parapet walls are standard on flat roofs and low-slope roofs but rare on traditional pitched residential roofs. If you own a home with a steep, shingled roof in a typical suburban neighborhood, you almost certainly don't have a parapet wall.

However, if you own a townhome, row house, or modern home with a flat roof section, you might have one. Commercial buildings, apartment complexes, and urban mixed-use structures almost always include parapet walls.

Here's a quick reference:

Roof Type | Parapet Wall Common? |

|---|---|

Flat roof | Yes, almost always |

Low-slope roof | Often, especially commercial |

Traditional pitched roof | Rarely |

Commercial buildings | Yes, standard |

Townhomes and row houses | Often, especially shared walls |

Flat Roof Parapet Wall Construction Basics

Understanding these basic components helps you communicate effectively with contractors and make informed decisions about parapet maintenance and repairs.

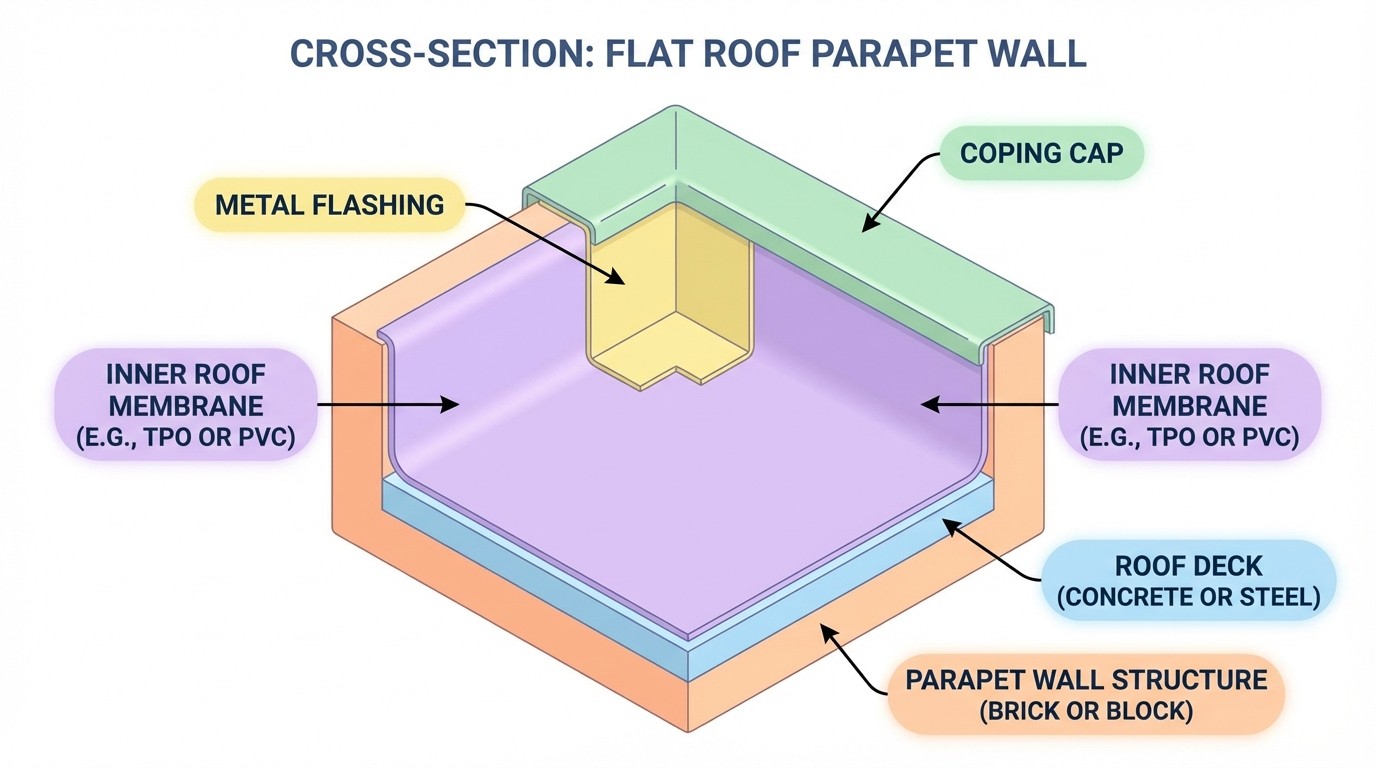

The parapet wall itself is typically an extension of the building's exterior wall, rising above the roof deck. The tricky part is keeping water out, since the wall faces weather on three sides: the exterior, the interior, and the top.

Here's how the waterproofing works:

Roof membrane: The waterproof layer covering your flat roof extends up the interior face of the parapet, usually 8 to 12 inches. This creates a continuous water barrier.

Flashing: Metal pieces cover the joint where the roof membrane meets the parapet wall, directing water away from the seam and onto the roof surface.

Coping: The protective cap on top sheds water to both sides. A properly installed coping overhangs the wall face slightly and includes drip edges to prevent water from running down the wall.

Ventilation: Some parapets include a small air space behind the wall cladding to prevent moisture from getting trapped inside.

When any component fails or gets installed incorrectly, water enters the wall. Once inside, water can travel down through the wall assembly and cause leaks that appear far from the actual entry point.

Common Parapet Wall Problems

Parapet walls face a challenge that standard exterior walls don't. Unlike walls protected by a roof overhang, parapets are exposed to rain, snow, wind, and sun on three sides. This constant exposure creates several common problems.

Cracks and mortar deterioration

Brick and masonry parapets develop cracks over time as buildings settle and materials expand and contract with temperature changes. Mortar joints are particularly vulnerable, especially in climates with freeze-thaw cycles. Water enters small cracks, freezes, expands, and makes the cracks larger. Over several seasons, this cycle causes significant deterioration.

You might notice vertical cracks at parapet corners or horizontal cracks along mortar joints. Even small cracks deserve attention because they allow water into the wall.

Water leaks and flashing failures

Flashing failure is the most common cause of parapet-related leaks. The metal flashing sealing the joint between roof and parapet takes a beating from weather and thermal expansion. Over time, flashing can pull away from the wall, develop holes, or lose its sealant.

When flashing fails, water runs down inside the wall cavity. The leak might not appear directly below the parapet. Instead, water can travel along framing members and show up as stains on interior walls or ceilings far from the actual entry point.

Coping damage

The coping cap on top of the parapet is your first defense against water entry. It's also the most exposed component, taking the full force of weather. Stone or concrete coping can crack, shift, or lose the sealant between sections. Metal coping can develop rust holes or pull away from fasteners.

When coping fails, water enters the top of the parapet wall and saturates everything below. This top-down water entry is particularly damaging because it affects the entire wall height.

Poor ventilation and moisture buildup

This problem is less visible but equally damaging. In a properly insulated building, the roof has insulation but the parapet wall extending above it often doesn't. This creates what contractors call a "cold bridge," where the uninsulated wall section becomes significantly colder than the interior space.

When warm, moist air from inside the building reaches this cold wall section, condensation forms. Over time, this moisture buildup leads to mold growth, wood rot, and wall deterioration. You might notice staining on interior walls near the roofline, musty odors, or visible mold.

How to Maintain Your Parapet Wall

Regular maintenance prevents small parapet problems from becoming expensive repairs. Most of the work involves simple inspections that help you catch issues early.

1. Inspect The Parapet At Least Twice A Year

Walk around your building in spring and fall to look at the parapet walls. You're checking for visible cracks in masonry, crumbling mortar joints, staining on the wall face, or sections that look different from the rest. For parapets that are difficult to inspect from ground level, consider scheduling a professional inspection to ensure thorough evaluation.

Pay extra attention after severe storms, heavy snow, or extended freezing weather.

2. Check Flashing And Coping For Damage

Look at the metal flashing where the roof meets the parapet. This area can be difficult to see from the ground, so you might need roof access or a professional inspection. Check for rust, holes, gaps, or sections that have pulled away from the wall.

Examine the coping cap for cracks, missing pieces, or gaps in the sealant between sections.

3. Clear Debris And Ensure Proper Drainage

Leaves, dirt, and debris can accumulate against the parapet base, trapping moisture against the roof membrane and flashing. After fall leaf drop and spring storms, clear away any buildup. Also check that roof drains near the parapet are clear and functioning.

4. Repair Cracks And Mortar Joints Quickly

Small cracks in masonry parapets become larger problems if left alone. Tuckpointing, the process of removing damaged mortar and replacing it with fresh mortar, is relatively inexpensive when damage is limited. Waiting until the wall is severely deteriorated can mean replacing entire parapet sections.

5. Schedule A Professional Roof Inspection

A qualified roofer can spot problems you can't see from the ground. During an inspection, the contractor examines flashing condition, checks the roof membrane where it meets the parapet, and assesses the overall condition of coping and wall.

Comparing detailed quotes from multiple qualified contractors helps you understand the full scope of necessary work and ensures you receive fair, transparent pricing for parapet repairs.

What Parapet Wall Repairs Cost

Parapet repair costs vary widely based on damage type and extent, materials involved, and wall accessibility. Simple tuckpointing might address minor mortar deterioration, while extensive water damage could require rebuilding wall sections, replacing flashing, and installing new coping.

The complexity comes from the fact that parapet repairs often involve both roofing and masonry work. For example, simple tuckpointing might cost $8-15 per square foot, while complete parapet rebuilding can range from $50-100 per linear foot depending on materials and height.

Common parapet repairs include:

Tuckpointing: Removing deteriorated mortar and replacing it with fresh mortar

Coping replacement: Removing damaged caps and installing new ones

Flashing replacement: Removing old flashing and installing new metal with proper sealant

Parapet rebuilding: Removing and reconstructing severely damaged wall sections

The best way to understand fair pricing in your area is to get multiple detailed quotes. If you’re replacing your entire roof plus parapet walls, the combined labor and materials can lower your overall bill by about 10–20% compared to doing them separately. For example, you might pay $1,000 for repairs if bundled, versus $1,200–$1,500 if done later as a standalone job.